CNC milling and turning 3D and 5 axis specialists

Here at PME Ltd we pride ourselves on producing the highest quality parts with competitive prices. Offering fast turnarounds, due to our 24-hour machine shop

Established 1988

The company was initially established in 1988 and has continued to expand with investments in new machinery and technology, which has enabled the company to compete in the quality end of sub – contract machining, allowing us to manufacture for a number of blue chip companies.

Fast Turn Around

We achieved ISO 9001:2000 in February 2003 and now have the latest version 9001:2015. With the acquisition of a 5Axis machining centre and the latest software from Hypermill, we now have the capability to offer the machining of 2D parts from DXF files and also 3D and 5Axis machining direct from IGES, STEP etc. From one off parts, prototype tooling, to small and large batch work, allowing a quick response and fast turn around from receiving.

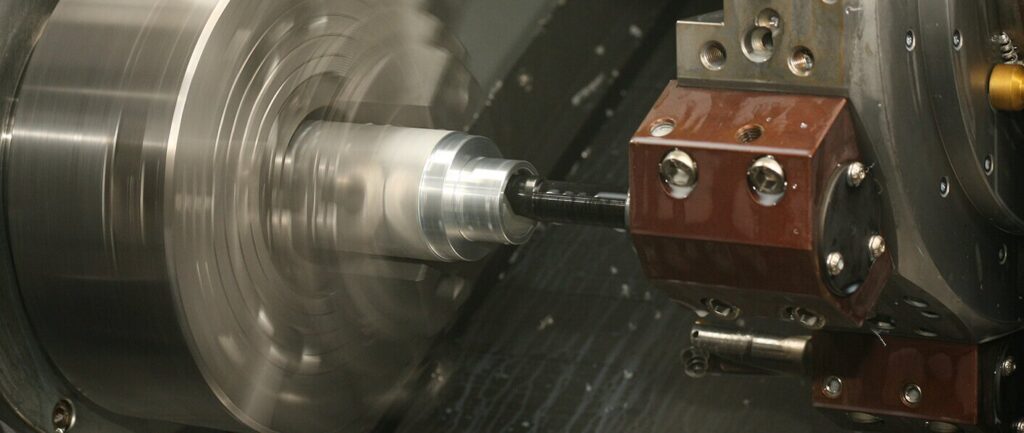

Various Machine Capacity

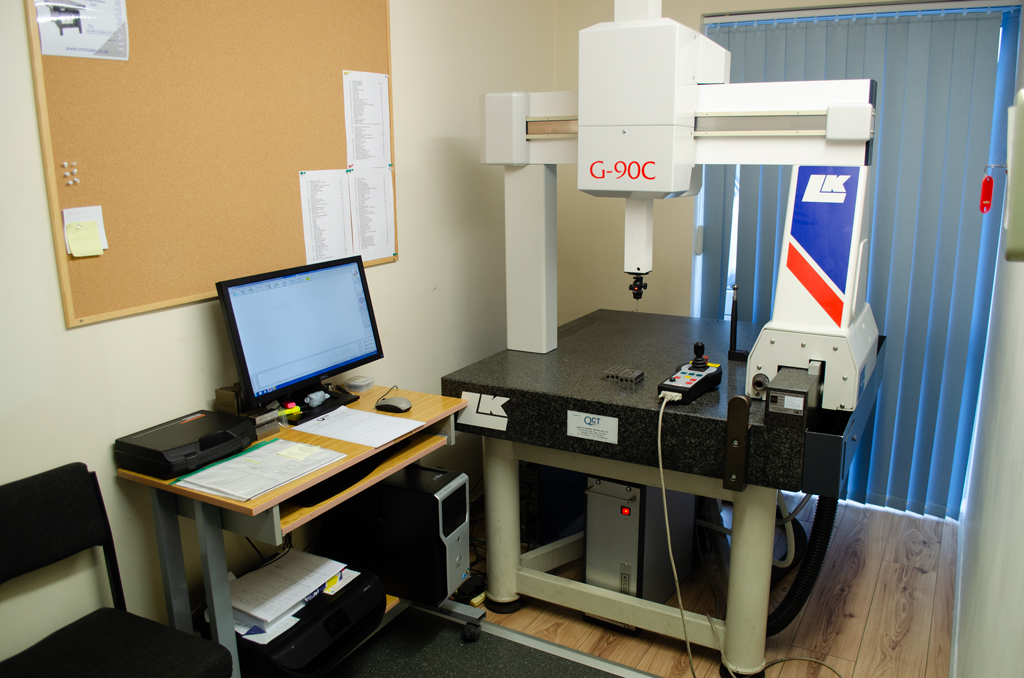

Our 24 hour machine shop consists of 15 CNC Milling machines, 3 CNC Turning centres and various manual machines including mills, lathes, grinders etc as well as a CMM measuring centre, enabling us to provide on request full CMM reports.

Our Services

In House Services

CNC milling 3, 4 and 5 axis capability, CNC turning large to small diameter, various manual machines, equipment, large machine shop able to undertake any volume of work.

Outside Process

We offer a wide variety of processes on our parts, for example Iridite-surtech 650-paint. Please click below for a full list.

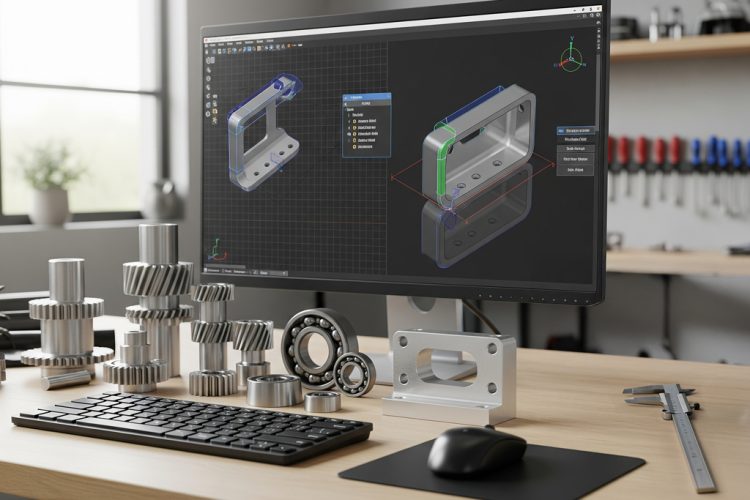

CAD/CAM Processes

We have 4 full cad-cam seats, enabling us to program direct from 3D models to our machines.

Honesty & Reliability

We understand the importance of building strong relationships with our customers that are based on honesty and reliability. By working tightly to your specific deadlines, we make sure that your products are manufactured and delivered to you on time.

Why Choose Us?

We work within incredibly tight tolerance levels, measured in microns and ‘safety critical parts’ for these demanding industries. Our skilled machinists and production engineers work with our state-of-the-art technology, and from a wide range of materials to produce precision engineered components.

Latest News

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.